Frequent problems in the varnishing process: Orange Peel

During the repainting process different problems and defects in the paint finish can arise, forcing to repeat the process from scratch, with the consequent loss of time and materials. One of the most common defects in the painting of guitars is the so-called orange peel effect.

What is the orange peel effect?

The name orange peel comes from the similarity of the final paint finish to orange peel. This problem is due to the fact that the paint does not stretch or level, which causes the surface to deform and increases the thickness of the final layer.

Causes of orange peel in spray painting of guitars

The reason for this defect can be related to several factors:

-

- The setting of the application equipment is incorrect. We must properly adjust the pressurization equipment, product flow and fan patterns.

- Application pressures that are too low will result in poor product atomization.

- The application viscosity is high. Another reason could be that the viscosity of the mixture is too high, which also means that the application viscosity is too high. To solve this problem, we can reduce the viscosity by slightly increasing the dilution of the mixture. We recommend starting with 10% solvent and then adjusting to the application equipment.

- The base coat is not too dry. We must always respect the drying time of the base. As a general rule a complete drying in nitrocellulose is obtained between 12 and 24 hours.

- Excessive product load. Excessive product loading per pass, and too far from the gun in relation to the workpiece, will result in an uneven coating, leading to the appearance of orange peel defects.

- Poor primer preparation and sanding. A correct preparation and sanding of the primer, always respecting the drying time of each process, will help us to obtain a uniform and optimized repainted surface.

Causes of orange peel in spray painting of guitars

In the case of spray application, all the above adjustments are already given by the spray content and the type of nozzle. What is critical, however, is the application distance and the speed of spray movement.

- Apply the spray at an average distance of 25 cm

- Shake the spray well.

- Do not stand still applying with the spray, always be in movement with smooth and continuous strokes.

- The trick is to apply at a speed and distance so that the paint covers enough, without sagging or leaving orange peel.

How to correct the orange peel effect on the paint?

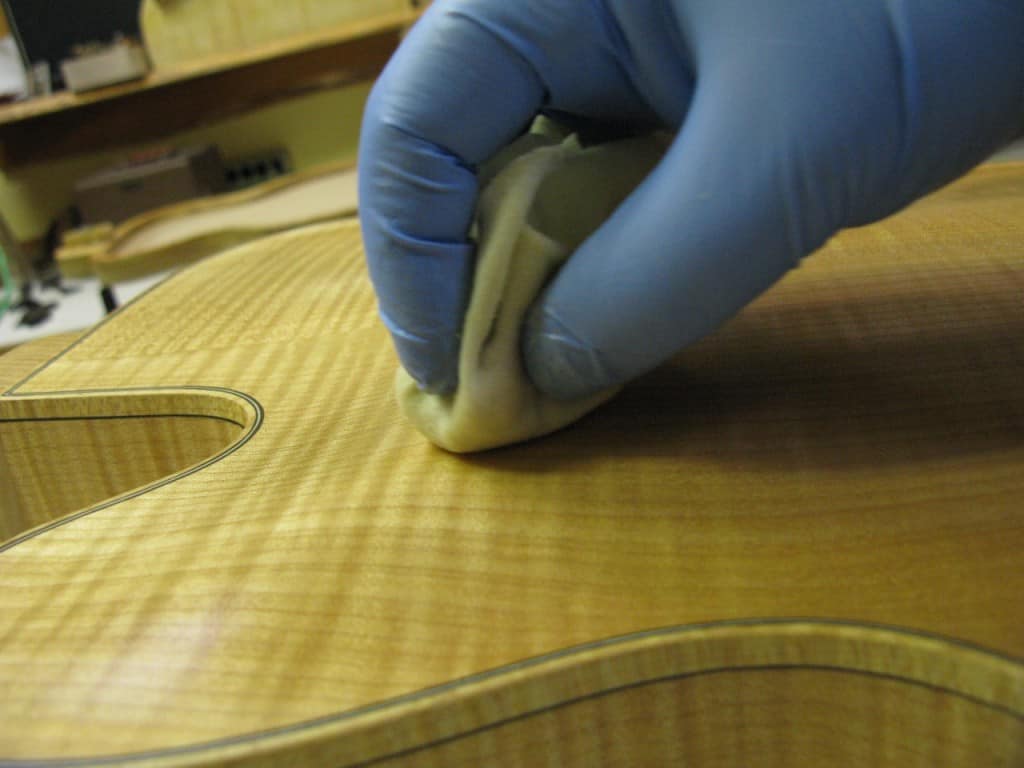

If the orange peel defect exists only on the surface of the piece, proceed as follows:

- First, we sand the defective area with P1500 sandpaper.

- We sand the surface with P2000 sandpaper.

- After sanding the surface, we will use a microfiber cloth to clean the resulting dust.

- Next, we will use a polishing machine for a quick cut polishing, applying pressure and a uniform movement. Finally, we will clean the area with ballet to evaluate the results obtained..

On the contrary, if there are still orange peel defects in the finish, and the thickness is too thick, the polish will not be enough.

In this hypothetical case we have to prepare the surface to start the painting process from scratch:

The first thing to do is to sand the surface according to the defects to be repaired until the orange peel is eliminated, and finally apply a finishing coat, always bearing in mind the above recommendations to avoid repeating the mistake.

To prevent this defect from appearing on the surface of your guitar, it is essential to follow these application tips, as well as the use of specific Nitorlack products.

These products have been formulated with a balanced evaporation of solvents to minimise this application defect. Also with the application of this solvent you can reduce the risk of this happening.

You can watch the tutorials both on our website and on Youtube, if you still have doubts you can ask us in our personalized support.