What is true in everything that is said about nitrocellulose? And why do guitarists still want their instruments finished with this material?

Clarence ‘Leo’ Fender, would be perplexed by the current guitar market. Legend has it that he was always looking to the future; That his next guitar and the processes used to do so would always improve in the last.

After Leo’s first production 65 years ago, many guitarists and experts passionately believe that old-style solvent-based nitrocellulose with a thin thickness finish is the best for “tone.”

Nitrocellulose varnish is more problematic and requires more time to apply than more current finishes such as polyester or polyurethane and is less durable, which means that the guitar is much more likely to have some aesthetic damage during its journey through the chain of supply and, of course, in the use of its owner.

Who would want that?

I am sure that Leo with his business and productive character would change that process for more modern finishes to improve production, but would it be better for the “tone”?

Detractors argue that it is pure nostalgia, lovers of that finish ensure that:

“The guitar ages better and will continue to ‘heal’ in the following years, as the solvent in the finish continued to evaporate and harden”

Either way, the facts are that Fender used both nitrocellulose and acrylic lacquer between 1950 and 60 Standards and finished in Custom Colors.

Originally developed for automobiles of the time, it is possible to identify which is which by the associated Dupont paint codes, which are defined with ‘Lucite’ (acrylic) or ‘Duco’ (nitrocellulose).

Lake Placid Blue (Lucite 2876-L), for example, is acrylic, while Sonic Blue was nitrocellulose (Duco 2295). The translucent finishes were always nitro, but not all colors had translucent finishes; If you see a white Strat with a yellow hue, for example, it probably has a top layer of transparent nitrocellulose. If it still looks very “white”, most likely there is no top layer.

The same effect occurs on guitars ending in Lake Placid Blue that may appear greener with age. In fact, acrylic paints developed because they were more resistant to yellowing and did not crack like nitrocellulose finishes. Nitro finishes, however, had a much more intense shine.

Two 60s Lake Placid Blue Jazzmasters – but the left guitar has a nitro top layer, which has yellowed over time

Nitrocellulose and the passage of time.

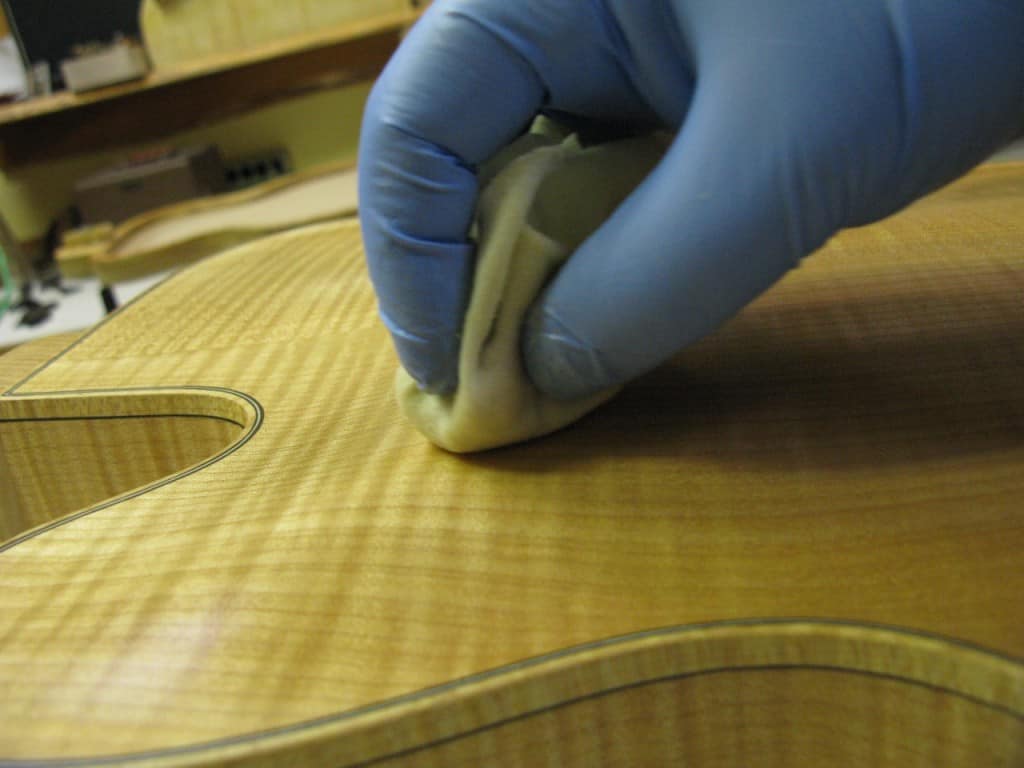

Nitrocellulose and acrylic components need to be mixed in solvent to be properly sprayed on a guitar, or even a car.

Once applied in several layers for days (each fuses with the next one, largely eliminating the need for sanding between layers), the guitar is allowed to dry before finally polishing. As we know now, that guitar would continue to ‘cure’ over the following years, since the solvent in the finish continued to evaporate and harden.

On some guitars, it never really did and the finish is smooth, but if you look at many of the 50s or early 60s Fender today, the finish is often extremely thin and almost fused with wood.

The differences in chemicals and color pigments currently used due to environmental requirements make Fender guitars between 50 and 65 so valuable and collectible.

“Modern nitro finishes are not exactly as they used to be although they differ quite little, but they are always better for the sound than the current polyester finishes of many serial guitars.”

As a result of the environmental requirements of different countries to guitar factories, together with the need to lower production costs, many of them (including Fender) have opted for more modern and current finishes such as polyurethanes and polyester.

The disadvantage is that they don’t feel or resemble vintage finishes, and they certainly don’t age like them – have you ever tried to make a “relic” in a modern polyester? It’s like scratching the glass.

Many people would see that as a great advantage – the late Leo Fender included – because his guitar is still bright and new, looking for much longer. For some, however, a guitar without a nitrocellulose finish is not a guitar.

Fender’s modern nitrocellulose finishes are not exactly the same as the old ones. There are hundreds of debates in international forums about polyurethane and polyester bottoms and covers under nitrocellulose … the so-called (Fender fullerplast)

Fender says that the finishing process used in Ensenada’s new instruments is a polyester / sealant sub-layer, followed by five layers of Seagrave L-4540 high-solids nitrocellulose lacquer for color and top layers.

So ¿why nitrocellulose?

By totally banishing polyester finishes, a good polyurethane finish with its right thickness can give us a good sound with a durable finish.

But if we want the vintage look of the old Fender finishes and that our instrument ages progressively, we definitely need a nitrocellulose finish.

In my opinion, nitrocellulose:

“Sounds better, ages better and feels better”

Finally, we would like to mention the article in our blog where we explain in detail how to perform this nitrocellulose varnishing process, and we detail which products to use from all those available on our website.